Is Plastic a Conductor?

When you think of materials that conduct electricity, metals like copper or aluminum likely come to mind. But what about plastic? The answer might surprise you… No, but yes also!

While traditionally considered an insulator, advancements in material science have led to the development of conductive plastics that are revolutionizing various industries.

ITO Touch, a leading US manufacturer of capacitive and resistive touch screens, is at the forefront of this innovation. We leverage the conductive properties of plastics to create cutting-edge touch screen solutions for diverse applications.

Understanding Conductivity

Before we delve into the world of conductive plastics, let’s briefly review what makes a material a conductor.

Electrical conductivity refers to a material’s ability to allow the flow of electric current. This flow is made possible by the presence of free electrons that can move easily within the material’s structure. Metals are excellent conductors because they have a large number of these free electrons. In contrast, insulators like traditional plastics have tightly bound electrons that resist the flow of current.

Making Plastic Conductive

So, how do we transform an insulator like plastic into a conductor? The key lies in incorporating conductive materials into the plastic matrix. There are several methods to achieve this:

- Adding Conductive Fillers: One common approach is to mix conductive fillers like carbon black, graphite, or metallic particles into the plastic resin. These fillers create pathways for electrons to flow, increasing the overall conductivity of the plastic.

- Creating Conductive Polymers: Another method involves developing inherently conductive polymers (ICPs). These special types of plastics have a molecular structure that allows for electron movement, making them intrinsically conductive.

- Applying Conductive Coatings: A third approach involves applying a thin conductive coating to the surface of the plastic. This coating can be made of materials like Indium Tin Oxide (ITO), which is known for its transparency and excellent conductivity.

ITO Touch and Conductive Plastics in Touch Screens

ITO Touch specializes in utilizing conductive plastics, particularly those with ITO coatings, in the manufacturing of touch screens. Here’s how it works:

- Capacitive Touch Screens: In capacitive touch screens, a layer of ITO-coated plastic is used as the conductive layer. When a finger touches the screen, it disrupts the electrostatic field, allowing the device to register the touch location.

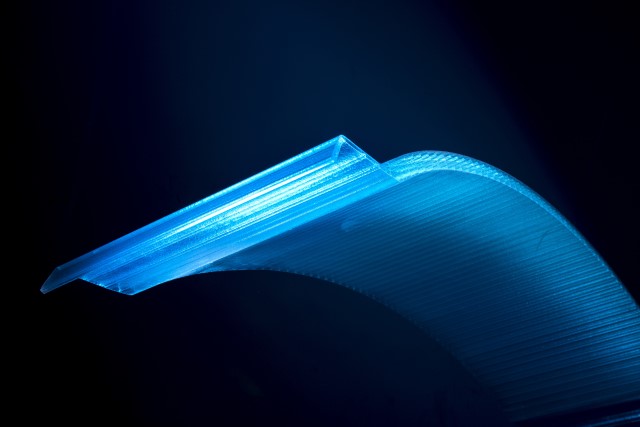

- Resistive Touch Screens: Resistive touch screens consist of multiple layers, including a flexible top layer and a rigid bottom layer, both coated with a conductive material. When pressure is applied to the top layer, it comes into contact with the bottom layer, registering the touch coordinates.

Benefits of Using Conductive Plastics in Touch Screens

- Flexibility and Durability: Conductive plastics offer greater flexibility compared to traditional glass-based touch screens. This makes them ideal for applications where the screen needs to be bendable or conform to curved surfaces.

- Lightweight: Plastics are generally lighter than glass, making them suitable for portable devices like smartphones and tablets.

- Cost-Effectiveness: In some cases, using conductive plastics can be more cost-effective than traditional materials, especially for large-scale production.

Applications Beyond Touch Screens

The applications of conductive plastics extend beyond touch screens. They are also used in:

- EMI Shielding: Conductive plastics can be used to create enclosures that protect electronic devices from electromagnetic interference.

- Anti-Static Packaging: Conductive plastics are used in packaging materials to prevent static electricity buildup, protecting sensitive electronic components during shipping and storage.

- Sensors: Conductive plastics can be incorporated into sensors to detect changes in pressure, temperature, or other environmental factors.

ITO Touch: Leading the Way in Conductive Plastic Technology

ITO Touch is committed to pushing the boundaries of conductive plastic technology. We leverage our expertise in material science and manufacturing processes to create innovative touch screen solutions that meet the evolving needs of various industries.

Whether you need capacitive or resistive touch screens, ITO Touch can provide customized solutions tailored to your specific requirements. Contact us today to explore the possibilities of conductive plastics and how they can enhance your products and applications.